Performance Testing Results

Containment Target : 10 ng/m³

Surrogate Powder Testing Result : 2.26 ng/m³

Equipment : Balance, Vials

Operation : Weighing, Dissolution, Dispensing

Test : Naproxen Sodium – 3 x 20mg

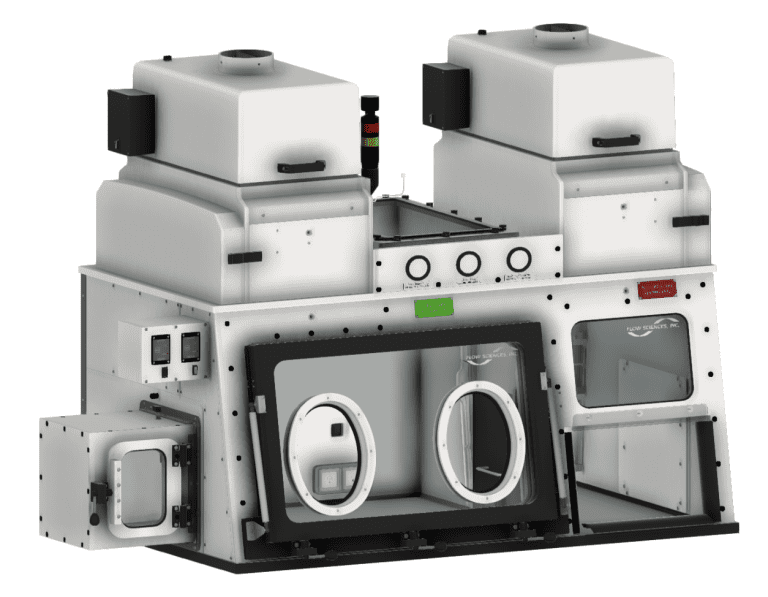

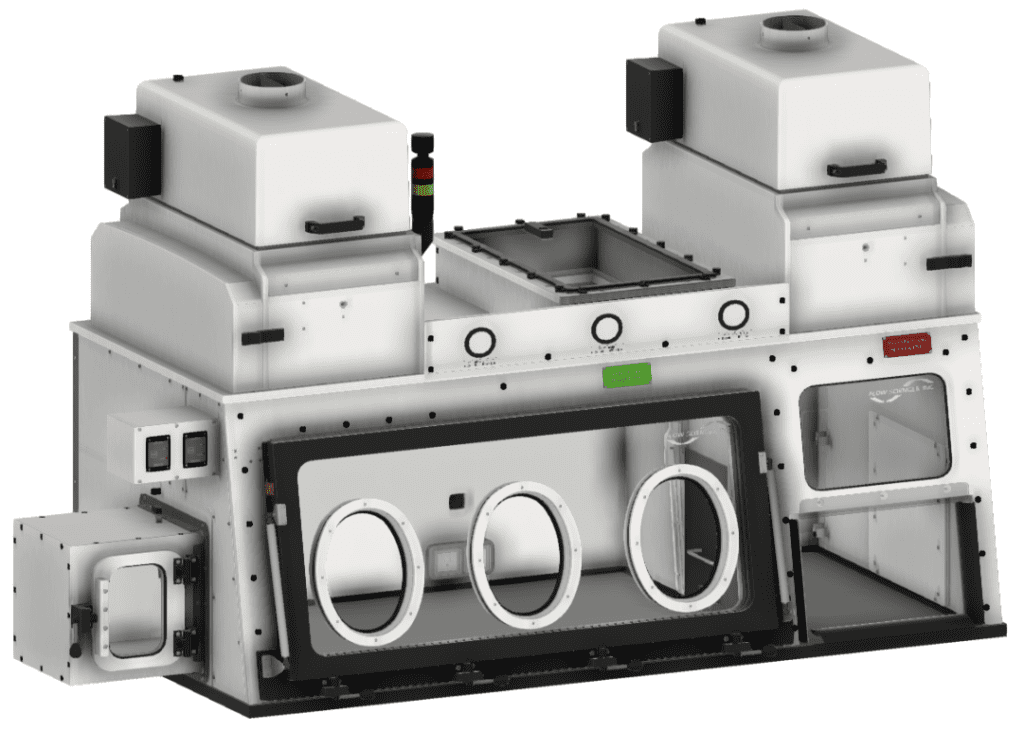

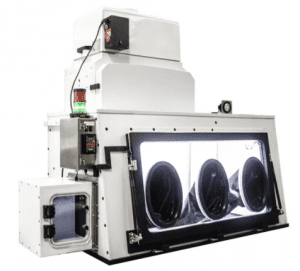

API Weighing and Solid Dosing Suite designed to provide personnel protection and product protection during the weighing of API powder and subsequent dosing (dose allocation) of weighed powder. Process low of product is facilitated by a pass-thru chamber between two enclosures: A 6 – foot Glovebox Workstation (left) and a 4 – foot Hybrid Isolator on the right.

Offers respiratory protection from substances assigned an Occupational Exposure Limit (OEL) within the airborne concentration range of 1000-5000 micrograms powder per cubic meter of air (1000-5000 ug/m3).

A stainless steel table with leveling pads is included for each enclosure. Leveling pads maintain balance stability to 7 decimal-places.

Left Side

- Glovebox Workstation – accommodates space for analytical balance such as the Mettler Toledo XPE Precision Balance

- Features lateral flow across the workspace to prevent cross-contamination of product while also protecting personnel from respiratory exposure

- Butyl gloves provide protection against dermal exposure to product

- Granite block under scale dampens vibrations and reduces statistical noise in regards to mass measurements

- LED light kit provides optimal viewing across the workspace

- Roxtec cable pass-thru membrane on rear of unit for ingress/egress of electrical and equipment cords and cables

- NEMA rated covered outlet

- Roxtec Cable Pass-thru on rear left allows for easy ingress/egress of equipment power cables and cords

- 8” diameter continuous liner allows safe removal of waste from interior of unit and storage of bag for next iteration of waste loading

- Hinged door to allow access to equipment after interior has been decontaminated

- Draft shield with 8” oval glove ports; draft shield is removable to yield a face opening of larger area (removing draft shield is recommended if conditions allow for a lower level of powder containment)

- Removable back plenum allows for easy access when cleaning the unit between runs

- Bottom – mounted 8” continuous liner facilitates seamless transition between waste removal tasks. In essence, the liner is designed to be used and subsequently primed for the next waste loadout procedure.

Accommodates space for 19.17” x 12.67” x 10.35” [487mm x 322mm x 263mm] within Glovebox Workstation (GBWS) on left side.

Right Side

For this enclosure suite, the right – side Hybrid Isolator is intended to enclose the dosing portion of the process. The removable glove panel style allows the user the option of using the enclosure with the glove panel or without. Additionally, the removable glove panel design triggers the automatic adjustment of fan speed for seamless transition between two face velocity settings.

Additional features include:

- Thimble connection (sold separately) facilitates connection to house exhaust system

Dimensions:

External Width: 106” [2692mm]; 160” [4064mm] with pass-thrus

External Depth: 34” [864mm]

Internal Height: 30.75 [781mm]

ECP603624ABD0

Polypropylene & Acrylic

EGG603624ABD0

Polypropylene & Glass

5′ ANALYTICAL PROCESS ISOLATOR

60″ External Width (1524mm)

36″ External Depth (914.4mm)

24″ Internal Height (610mm)

ECP723624ABD0

Polypropylene & Acrylic

ECG723624ABD0

Polypropylene & Glass

6′ ANALYTICAL PROCESS ISOLATOR

72″ External Width (1829.8mm)

36″ External Depth (914.4mm)

24″ Internal Height (610mm)

ANALYTICAL PROCESS ISOLATOR SYSTEMS

Working with a specific piece of equipment? Our design history has led to many custom solutions created for equipment that

is highly likely to be similar or exact to your specific equipment.

Our sales, engineering, and project management staff begin by creating a unified understanding of every customer’s

process and goals through the completion of the Custom Quote Request Form.