FROM HERE

THROUGH ON-SITE PREPARATION

TO HERE

Dr. Bob Haugen,

Flow Sciences; 10/22/2018

Abstract:

Many people who design labs or work in them may have little idea of how hard it is to get large equipment set up and working in a modern lab environment!

The trades responsible for these feats are often not appreciated for what they do. This paper will review ways to minimize installation issues (expenses) before products are deliveredusing many of the same steps discussed in previously published papers1:

Even though delivering, unloading, staging, distributing, and assembling are required steps in all lab construction,there are design aspects of lab equipment that can contributeto its successful field installation.

SHIPPING

While this whole delivery issue is separate from the manufacturing phase of heavy lab equipment, a product cannot become useful until it travels from the on-site delivery trailer to the actual lab areain the facility where it is to be installed.

I have seen cases where a matter of inches prevented a product from making a hallway turn or being loaded into an elevator. If no advance planning has been undertaken, local contractors are often forced to either partly disassemble the equipment or temporarily disassemble the building itself. These adventures can be costly if necessary arrangements have not been anticipated.

Flow Sciences and other lab equipment manufacturers have actually taken steps in product design to minimize the kind of distribution difficulty outlined above.

Flow Sciences fume hoods, base cabinets, and plumbing components are modularized in design so various sub-parts are easy to separate and move to the installation site independently when the whole unit cannot make it in one piece.

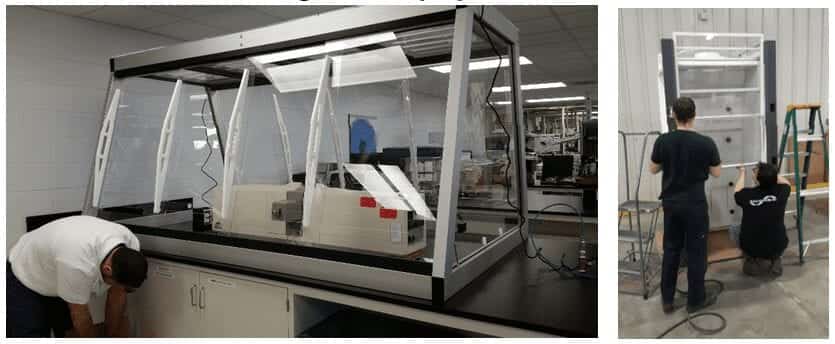

Below is an actual field example. This large multi-sashed unit was disassembled for carrying to the user’s laboratory in the lab elevator and then re-assembled.

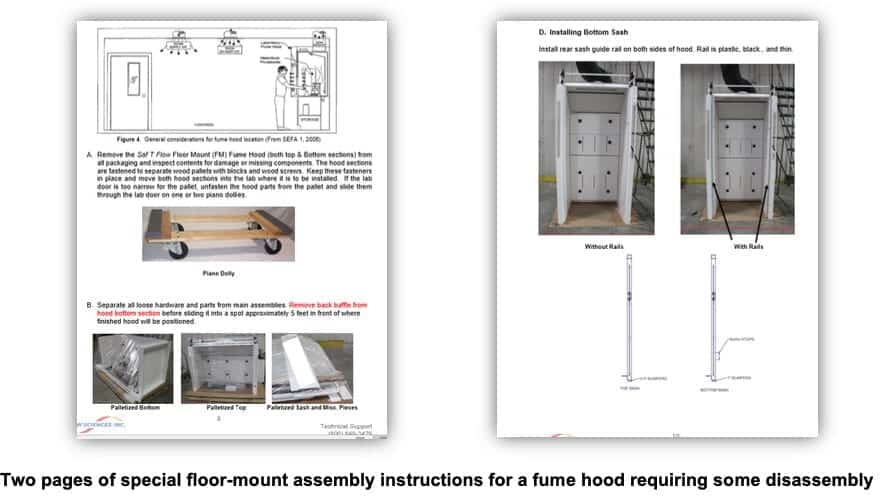

In another case, a floor-mount fume hood was divided into three separate pallets of materials to avoid disrupting hallway traffic and tight corners at a working lab. Not only did this step allow installers to identify components, the manual gave easy-to-follow re-assembly steps reviewed in the next section!

ASSEMBLY

Documenting this procedure is typically covered in the owner/operator manual. Because we now all operate in the age of electronic media, FSI can modify or expand a standard manual to include assembly/disassembly instructions based on customer input. Our inside sales team was alerted by the customer receiving this floor mount fume hood that the path to the target lab included sharp corners and low ceilings. See below special assembly pages included in this floor-mount fume hood manual.

INSTALLATION

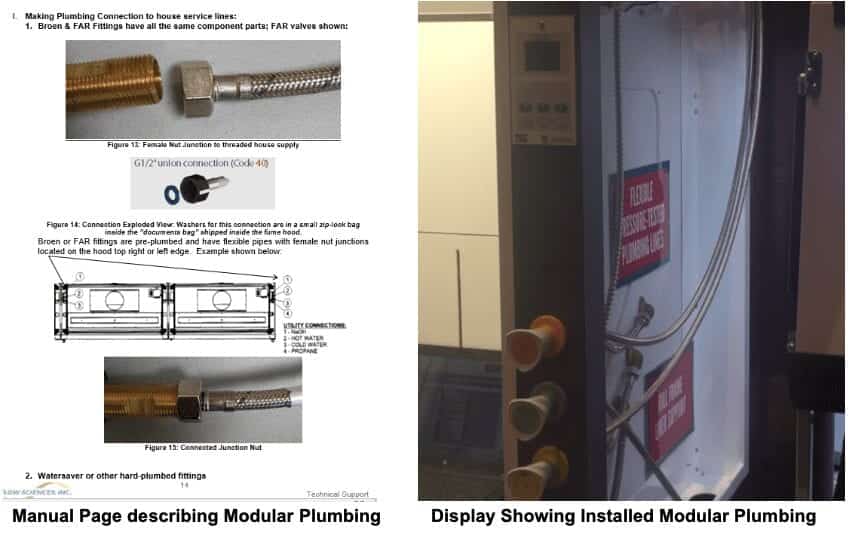

Flow Sciences and other equipment manufacturers have moved toward flexible plumbing within the fume hood itself 2, 3, 4because such fittings and plumbing eliminate hard plumbing with fragile sweat solder joints which can break free during transit. Plumbing is also easily attached to threaded connectors already installed by the building plumber. Again, this option is outlined in the manual.

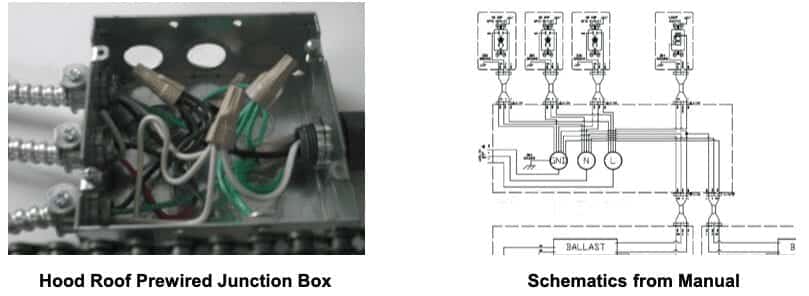

Electrical devices provided with the product are Pre-Wired in all cases to a junction box. Schematics and wiring diagrams are in the installation manual.

Miscellaneous information on safe fume hood use, velocity alarms, cabinets are all in their respective manuals included with shipment.

CONCLUSION

Errors may not occur if there is clear and comprehensive communication between the manufacturer and lab customer! Fine laboratory equipment is out there, but knowing where it comes into the building and where it must go must be clearly understood by all parties in the manufacturing/installation process. Large equipment is, well, LARGE.

It may need to go up elevators, through narrow hallways, and into labs through narrow doors. In many cases this requires partial disassembly, distribution, and reassembly at the installation location. These challenges may exist in both new construction and inevitably in operating labs requiring new equipment.

In spite of these challenges, the modular design technologies of newer lab equipment and more flexible electronic literature and communication formats offer hope for large exhaust equipment to be installed quickly with few problems.

Other issues with new, large equipment include incorporating new exhaust systems into building air balance, adjusting heating and cooling loads for thermostatic control, and making certain additional duct runs are incorporated into the building structure.

Footnotes:

- Necessity is the Mother of Innovation; https://flowsciences.com/necessity-is-the-mother-of-innovation/

- Broen Valves, https://www.broen-lab.com/Files/Images/brochures/99B0056%20-%20BROEN-LAB%20UniFlex%20Front%20Control%20Valves%20and%20Outlets-BASIC.pdf

- Nuova FAR Valves, https://www.far-mds.com/products/

- Watersaver valves, https://wsflab.com/flexible-laboratory-fittings/