FAT

Fitzmill L1A & Quadro Comil Glovebox

Glovebox Workstation Glovebox and Comil Glovebox and Fitzmill Process:Flow Sciences was approached to design a glovebox that would enclose milling processes done by either a Fitzmill L1A or a Quadro Comil. Containment Design:A panel interface on the right side of the glovebox allowed for the connection of either piece of equipment that would sit on …

Memmert VO 200 Vacuum Oven Enclosure

Memmert VO 200 Vacuum Oven Enclosure Finding a solution to provide personnel protection when working with Highly Potent Active Pharmaceutical Ingredients (HPAPI) is very tricky. In a business sector where regulations and policies are prevalent, exposure control options are limiting; both physically and financially. Laboratory operations require unwavering precision and physical/financial …

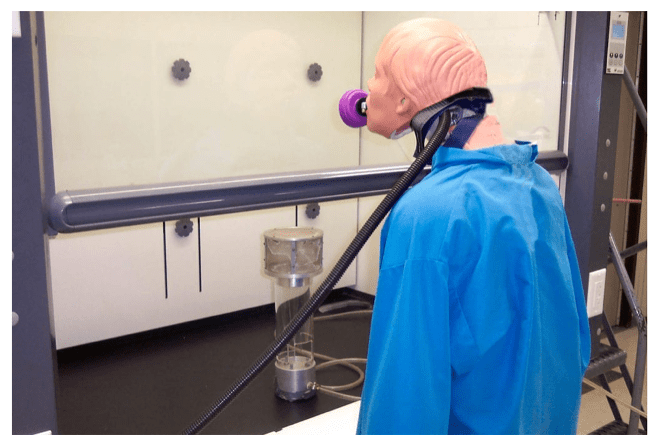

FSI Testing Performance – Laboratory Testing Services

LELAND, NC, December 18, 2018 —Flow Sciences, Inc. (FSI) evaluates and ensures that every enclosure shipped to their customer meets all relevant standards. FSI performs procedures from the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) 110-2016 – Methods of Testing Performance of Laboratory Fume Hoods. Examples of testing procedures include flow visualization …

FSI Testing Performance – Laboratory Testing Services Read More »

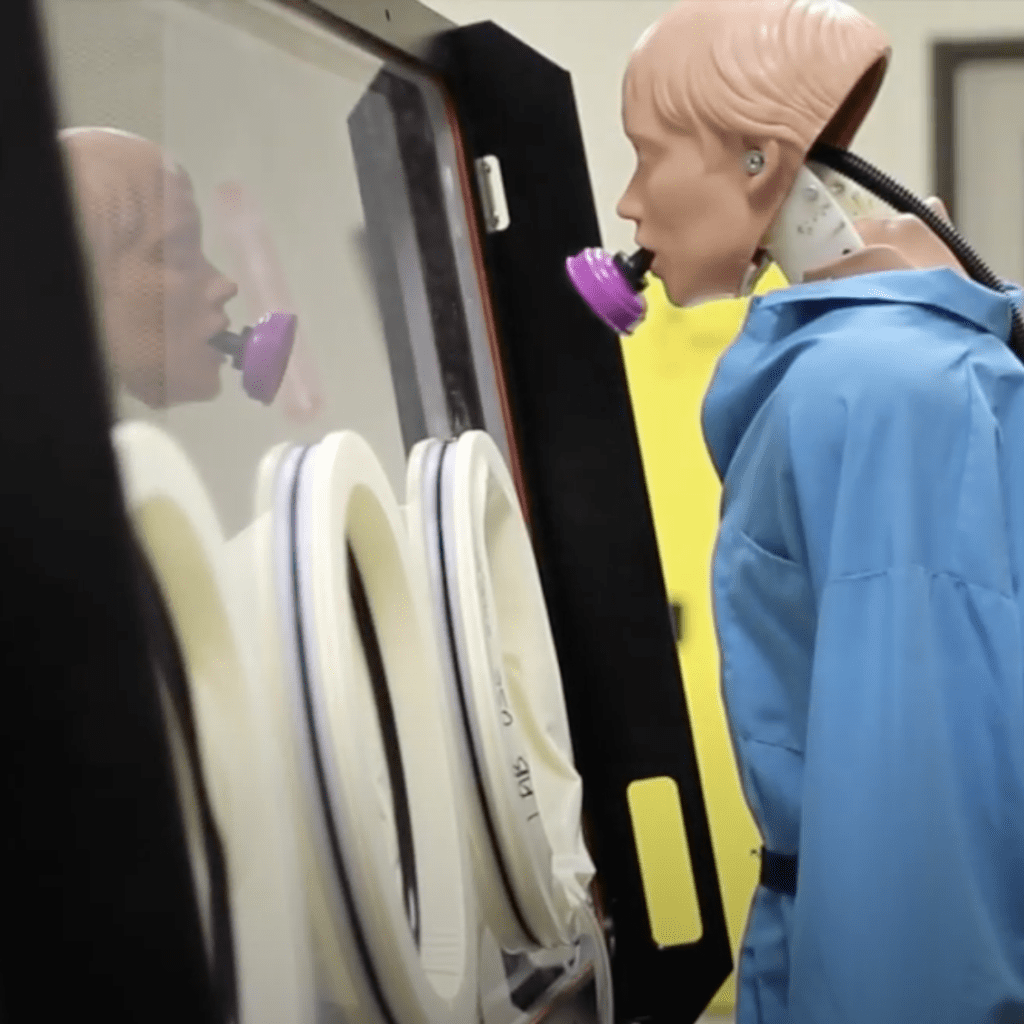

Performance Validation by Third Party Industrial Hygienists

Flow Sciences, a leading provider of containment solutions for laboratory, pilot plant, and manufacturing facilities consults with third party industrial hygienists to conduct in-house Factory Acceptance Tests (FATs) and Site Acceptance Tests (SATs) to ensure customers’ products perform at the level they need. Flow Sciences partners with experienced third-party Industrial Hygiene (IH) consulting professionals from partnering …

Performance Validation by Third Party Industrial Hygienists Read More »