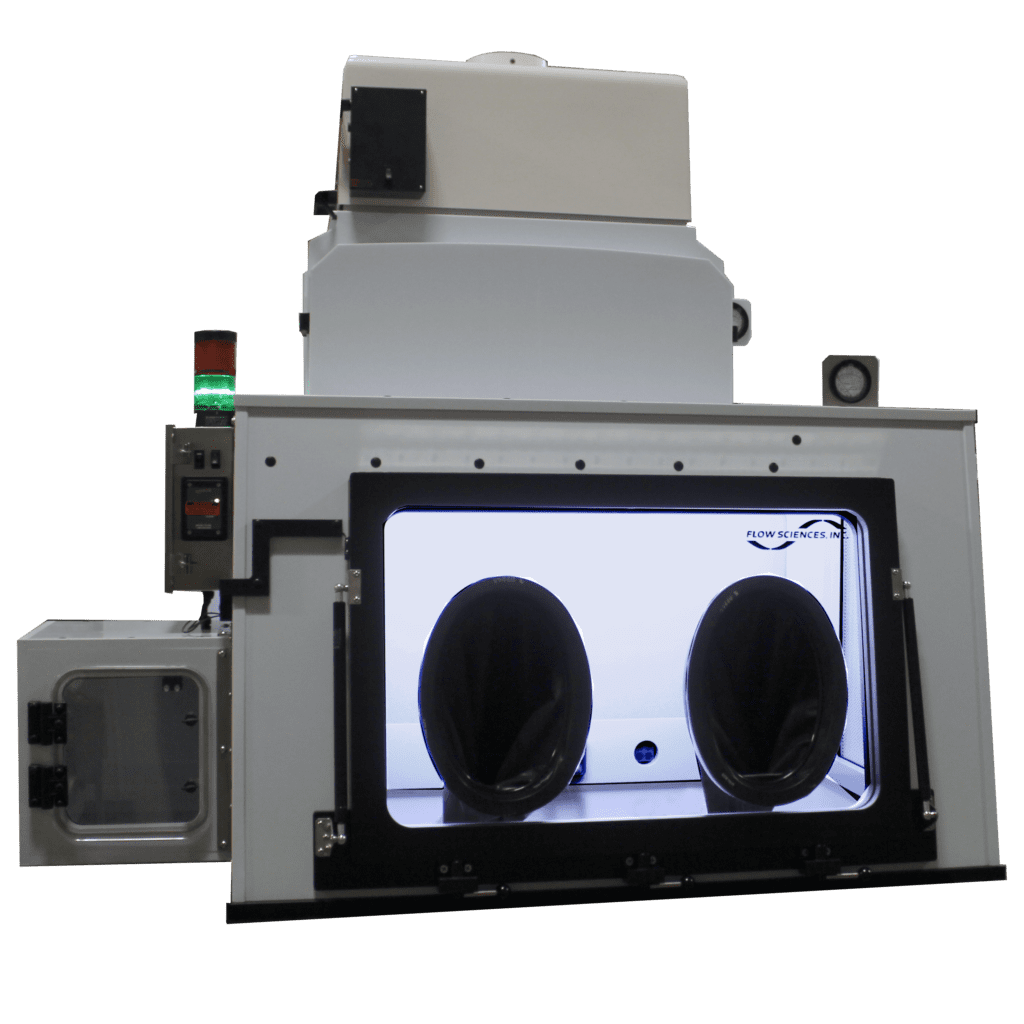

Nicolet FRIT Glovebox Workstation designed to provide personnel protection from powdered substances down to a respiratory exposure concentration of less than 1 microgram per cubic meter air (< 1 ug/m3) and product protection during Fourier Transform Infrared Spectrometry (FTIR) operations involving a Nicolet iS10 FTIR spectrometer*. Enclosure features polypropylene superstructure and acrylic viewing panels on the front door and on each side.

Enclosure features (2x) 10” oval glove ports and butyl gloves for safe manipulation of equipment / product inside the enclosure. Also features control box with integrated airflow alarm and stack light which alerts the operator when containment is established (green light indicator), when the left side access door is open (amber light indicator), and when containment is not established (red light indicator); control box also features audible alarm to alert the user when face velocity measurement is below the setpoint calibrated by the certifier.

Right-side inlet filter and top-mounted Dual-HEPA fan / filter housing facilitate lateral flow of air across the workspace. Lateral flow protects product from cross-contamination from other products inside enclosure and entrained, ambient particulate from the surrounding environment.

*Nicolet iS10 (W x D x H) dimensions = 550mm x 570mm x 250mm (21.7” x 22.4”” x 9.8”)

Additional features include:

- 8” Continuous Liner flange on right side for consistent reusability of waste removal system

- Top mount fan / filter housing features Bag-In-Bag-Out (BIBO) system for safe replacement of primary HEPA filter

- (2x) LED Lighting provides optimal viewing across the workspace

- 2 gang modular outlet on back wall of enclosure allows electrical connection inside the unit

- Gas shocks on front door facilitates ease when loading / unloading equipment and product

Dimensions:

External Width: 68.46”

External Depth: 32.00”

Internal Height: 30.00”

FSI Category 7-8